2023 marked a significant turning point for Boom Supersonic as they embarked on a groundbreaking journey to construct and operate their revolutionary Overture supersonic transport aircraft.

This remarkable endeavor aims to bring back the era of supersonic commercial travel, which has been dormant since the Concorde.

The previous year was undeniably dedicated to sourcing skilled subcontractors who could transform their visionary concept into a tangible reality.

Summary

- Boom Supersonic established a Superfactory in North Carolina, benefiting from low taxes and access to talent.

- The Superfactory’s structural beams have been installed, indicating progress in construction.

- Suppliers for the Symphony supersonic engine, including Florida Turbine Technologies and GE Additive, were secured.

- Aernnova, Leonardo, and Aciturri were chosen to fine-tune the wings, fuselage, and tails respectively.

- Latecoere was selected to define the electrical wiring system architecture for Overture.

- Honeywell will install the Anthem integrated cockpit suite, offering advanced avionics for the Overture flight decks.

- Boom Supersonic’s partnerships for critical subsystems have propelled its ability to manufacture Overture, showcasing significant growth in 2023.

Boom Overture Superfactory

Now, let’s delve into the remarkable strides that Boom Supersonic has accomplished thus far.

To kickstart the year, they established a state-of-the-art Superfactory in the vibrant state of North Carolina.

Starting an aircraft manufacturing plant in Greensboro, North Carolina comes with numerous advantages.

According to Christopher Chung, the CEO of the Economic Development Partnership of North Carolina, the state offers an abundance of resources and access to highly skilled talent.

What’s more, North Carolina boasts the lowest corporate income tax rate in the entire United States, currently standing at 2.5%.

This rate is set to decrease further and eventually reach zero by the year 2030.

In this location, state taxes are kept at a minimum, electricity costs are affordable, and there is no state sales tax on aviation gasoline/jet fuel.

This means that both employees and employers can travel longer distances for a lower cost.

The Superfactory has already completed the installation of all its structural beams, as stated in a press release by Boom Supersonic on September 20th.

Boom Overture Suppliers

Undoubtedly, securing suppliers for Symphony is the most noteworthy achievement for Boom Supersonic in 2023.

The supersonic engine that will be installed on every Overture is called Symphony.

Each Overture aircraft will be equipped with four of these powerful engines.

Florida Turbine Technologies has been selected to design the engine, while GE Additive will provide consulting services for additive technology design.

Additionally, StandardAero will handle the maintenance of these engines.

Each of these engines will produce 35,000 pounds of thrust without the need for an afterburner, and they will be specifically designed to run on 100% sustainable aviation fuel (SAF).

According to recent announcements in June, Aernnova, a Spanish company, will collaborate with Boom Supersonic to refine the wings for supersonic cruise flights.

In the meantime, Leonardo, an Italian aerospace firm, will assist Boom Supersonic in perfecting the fuselage, while Aciturri, a Spanish company, will be responsible for the design and development of the tails.

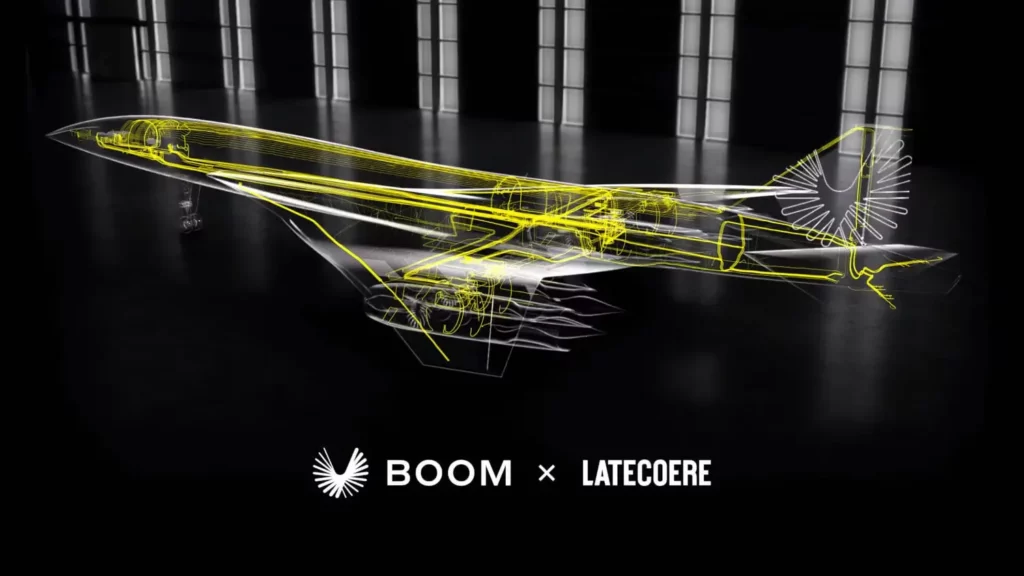

Boom Supersonic has recently chosen Latecoere of Toulouse, France, to collaborate on the development of Overture’s comprehensive electrical wiring interconnection system architecture.

In each Overture jet, Boom Supersonic aims to incorporate an impressive 64 miles (103 kilometers) of wiring, equivalent to the wiring found in a Boeing 787 aircraft, as reported by Avionics International.

Boom Overture Cockpit Instruments

What’s a cockpit without its instruments?

Boom Supersonic has partnered with Honeywell, a top avionics manufacturer, to equip Overture flight decks with their cutting-edge Anthem integrated cockpit suite.

Unlike the Concorde, the Boom Aerospace Overture cockpit will not rely on numerous round dials or a three-person crew to safely traverse the Atlantic at supersonic speeds.

Indeed, the year 2023 witnessed an extraordinary surge in Boom Supersonic’s capacity to produce Overture, owing to the establishment of crucial partnerships for essential subsystems.

This remarkable progress marked a significant milestone in their development journey.